Production Procedures

Production Procedures

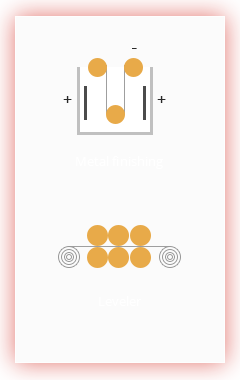

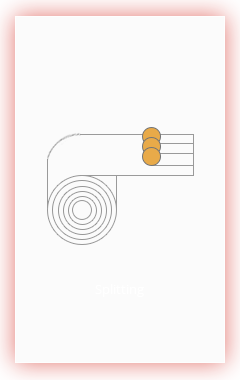

Equipment

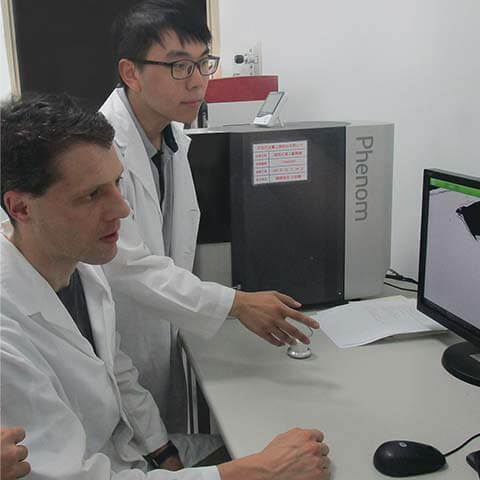

The production and R&D teams of MINCHALI have been committed to upgrading the level of production technology by exchanging knowledge with other world-class leading manufacturers. The goal is to create copper items of even higher quality.

MINCHALI meets the high standards and demands of each client by using pure acid copper as the raw material in casting and through the complex procedures of hot rolling, cold rolling, annealing and degreasing. We also conduct quality control with the advanced automated CCD device.

In the pursuit of achieving high quality in compliance with green norms, MINCHALI is committed to manufacturing products which satisfy both the needs and expectations of our clients. We expect to be technical leaders in the global copper metallurgy industry.