Products

Brass

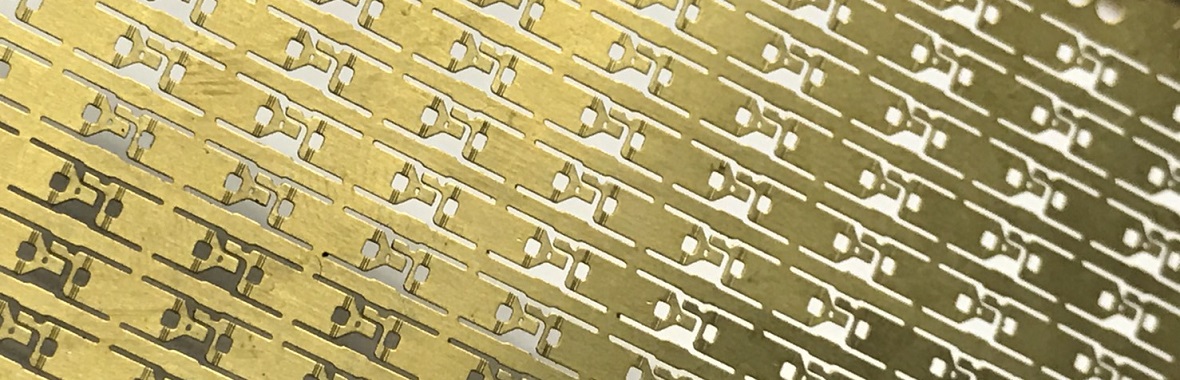

Brass is a copper-zinc alloy metal with fine ductility and workability in punching processes. It is suitable for making precision instruments due to its excellent mechanical workability and wear-resistant performance. It is used to make parts of ships and vessels because of its corrosion-resistant nature. Its golden luster becomes sheer and bright after polishing, so it is utilized to bring out a sense of craftsmanship in products such as musical instruments and sanitary ware.

Brass: A fine look with excellent workability in punching processes.

Chemical Composition

| Type No. | Alloy No. | Symbol | Chemical Composition | Features & Application | |||

|---|---|---|---|---|---|---|---|

| Plate Ribbon | Cu | Fe | Pb | Zn | |||

|

BS |

C2600 |

C2600P |

68.5~71.5 | <0.05 | <0.05 |

remainder |

Features: Good elongation; being pressed and processed well; being electroplated well. |

| C2680 |

C2680P |

64.0~68.0 | <0.05 | <0.05 |

remainder |

||

| C2801 |

C2801P |

59.0~62.0 | <0.07 | <0.10 |

remainder |

||

| Others | - | Negotiation | |||||

Mechanical Properties & Physical properties

| Alloy No. | Mechanical Properties | Physical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quality Grade | Symbol |

Tensile Strength (Kgf/mm2) |

Elongation | Hardness | Modulus of elasticity (GPa) |

Electric Conductivity (%IACS) |

Specific heat capacity ﹝J/kg·k﹞ |

Density (g/cm3) |

Coefficient of thermal expansion (x10-6/K) |

Thermal conductivity W/(m·K) |

||

| Plate Ribbon | Standards | Minchali | ||||||||||

| C2600 | O |

C2600P-O |

>28 | >40 | — | <90 | 110 | 24.0~28.7 | 377 | 8.53 | 19.9 | 121 |

| 1/4H |

C2600P-1/4H |

33~42 | >35 | 75~125 | 90~110 | |||||||

| 1/2H |

C2600P-1/2H |

36~45 | >28 | 85~145 | 110~135 | |||||||

| 3/4H |

C2600P-3/4H |

39~50 | >20 | 95~160 | 130~145 | |||||||

| H |

C2600P-H |

42~55 | — | 105~175 | 140~160 | |||||||

| EH |

C2600P-EH |

53~63 | — | 145~195 | >160 | |||||||

| SH |

C2600P-SH |

58~68 | — | 165~215 | >180 | |||||||

| ESH |

C2600P-ESH |

>63.5 | — | >180 | >185 | |||||||

| C2680 | O |

C2680P-O |

>28 | >40 | — | <90 | 103 | 24.0~27.8 | 377 | 8.47 | 20.3 | 117 |

| 1/4H |

C2680P-1/4H |

33~42 | >35 | 75~125 | 90~110 | |||||||

| 1/2H |

C2680P-1/2H |

36~45 | >28 | 85~145 | 110~135 | |||||||

| 3/4H |

C2680P-3/4H |

39~50 | >20 | 95~165 | 130~145 | |||||||

| H |

C2680P-H |

42~55 | — | 105~175 | 140~160 | |||||||

| EH |

C2680P-EH |

53~63 | — | 145~195 | >160 | |||||||

| SH |

C2680P-SH |

58~68 | — | 165~215 | >180 | |||||||

| ESH |

C2680P-ESH |

>63.5 | — | >180 | >185 | |||||||

| C2801 | O |

C2801P-O |

>33 | >35 | — | <100 | 103 | 24.3~28.3 | 377 | 8.39 | 20.8 | 121 |

| 1/4H |

C2801P-1/4H |

36~45 | >25 | 85~145 | 90~115 | |||||||

| 1/2H |

C2801P-1/2H |

42~50 | >15 | 105~160 | 110~140 | |||||||

| 3/4H |

C2801P-3/4H |

40~50 | >10 | — | 120~150 | |||||||

| H |

C2801P-H |

>48 | — | >130 | >140 | |||||||

| EH |

C2801P-EH |

>55 | — | — | >160 | |||||||